Equipment List

Horizontal Machining

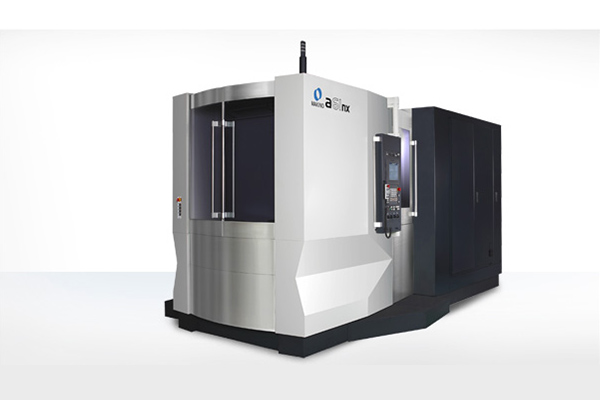

a61nx Horizontal Machining Center

The a61nx is a 500mm, 40-taper production horizontal machining center. The a51nx and a61nx share key machine technologies that take part productivity, accuracy and machine reliability to the next level. The 14,000-rpm high-speed, high-power spindle features 240 Nm of torque, well suited for automotive part production. Non-cut times are minimized through 1G axis acceleration and a standard direct-drive motor B axis. Robust casting design and roller-type linear guides ensure that the entire a61nx work envelope can be effectively utilized. The a61nx production machining center is available in a tall column (730mm) version for part applications that require larger strokes but do not need 50-taper spindles. Unique way-cover design, dual-supported tool-change arm and Makino spindle technology provide the foundation for industry-leading reliability.

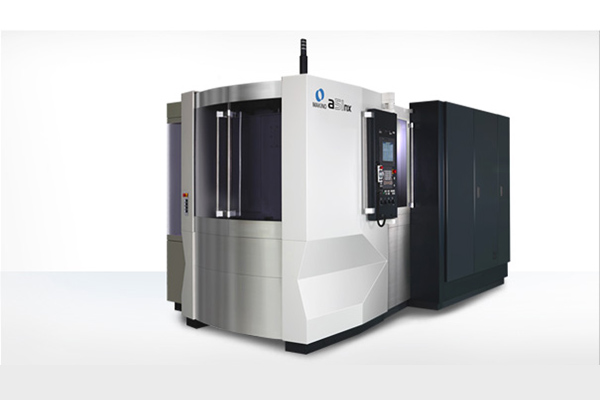

a51nx Horizontal Machining Center

The Makino a51nx is a 400mm horizontal machining center that builds on the highly successful a51 platform with key high performance machining technologies that take productivity, accuracy and machine reliability to the next level. The 14,000-rpm high-speed, high-power spindle features 240 Nm of torque, making it well suited for ferrous and non-ferrous part production. 1G axis acceleration and a standard direct-drive motor B-axis minimizes non-cut times, whereas a robust casting design and roller-type linear guides ensure the entire a51nx work envelope can be effectively utilized. Additionally, one-piece way covers (X and Z) and a dual-supported tool-change arm provide the foundation for industry-leading reliability and high performance machining capability.

Multi-Axis Turning

Eurotech B446-SY2 Multi-Axis Turning Center

The Eurotech B446-SY2 Multi-Axis Turning Center is an 11 - Axis Turning/Milling Center CNC lathe. Rowe Dynamics is able to provide you with the capacity and capabilities your project needs, while also delivering the most competitive pricing and lead times. By performing both standard universal turning & complete machining of complex work-pieces in 1-Op, combining live tools, C-axis, Y-axis, and sub-spindle in one of the world's fastest 11 axis, horizontal turn/mill machine. High-output 1-3/4 - 2-5/8" universal turn/mill centers with 20 HP spindle, Fanuc 31iTT, 2 12-station turrets, barfeed interface, C-axis, 5-hp live tooling, programmable sub-spindle, 2Y-axis, fully automated parts handling.

Top Automazioni X-Files Bar Feeder

The Top Automation X-Files-S is a 12' automatic loader suitable for fixed head lathes, it can work bars up to 80mm in diameter. The X-File-S is an automatic loader that does not require tooling but self-adjusts in 60 seconds setting the parameters of the bar worked on the PLC. All this is possible thanks to a top Automazioni patent that allows the rests, positioned every 300mm along the entire loader guide channel, to self-adjust to a single mm from the diameter of the bar to be machined. This system reduces set-up times and provides greater bar rotation stability than a traditional loader as it is supported on more points than the lathe clamp and loader.

Horizontal Band Saw

Cosen Dual Column Fully Programmable Automatic Horizontal C-420NC Band Saw

Smart NC-100 (SNC100) technology provides most of the benefits of NC controlled saws at a mere fraction of the cost. SNC100 controls are programmable up to 100 different jobs including quantity and length of cut. The control automatically compensates for Kerf loss after data input and requires no manual calculation of number of times to index. Rugged, Dependable, and Advanced Technology, are all words that describe every Cosen SNC-100 Series Sawing Machine.

We also offer Job Shop Management software

JobBOSS2 will give shop owners even more control over how they scale their businesses, grow revenue, and maximize profitability. It's designed to solve the biggest pain points of running high-performing manufacturing businesses in the modern age.