CNC Manufacturing Design Analysis

Rowe Dynamics Inc. can provide manufacturing consulting designed to fit the specific needs of our customers. We consult for customers using innovative procedures to streamline manufacturing techniques and the flow of information and materials to streamline logistics. This helps us reduce time and material inefficiencies and allows for constant system optimization. Efficiency through proper project management allows us to ensure our customers competitive edge.

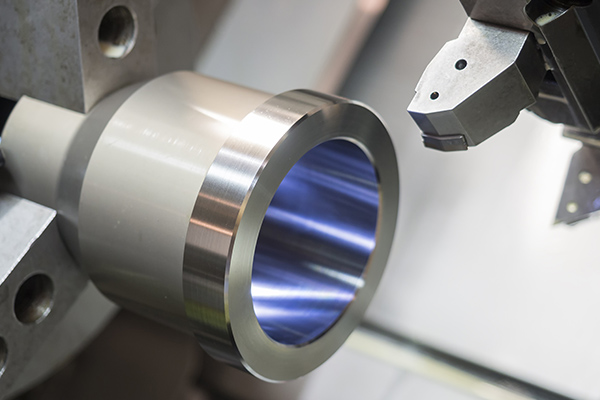

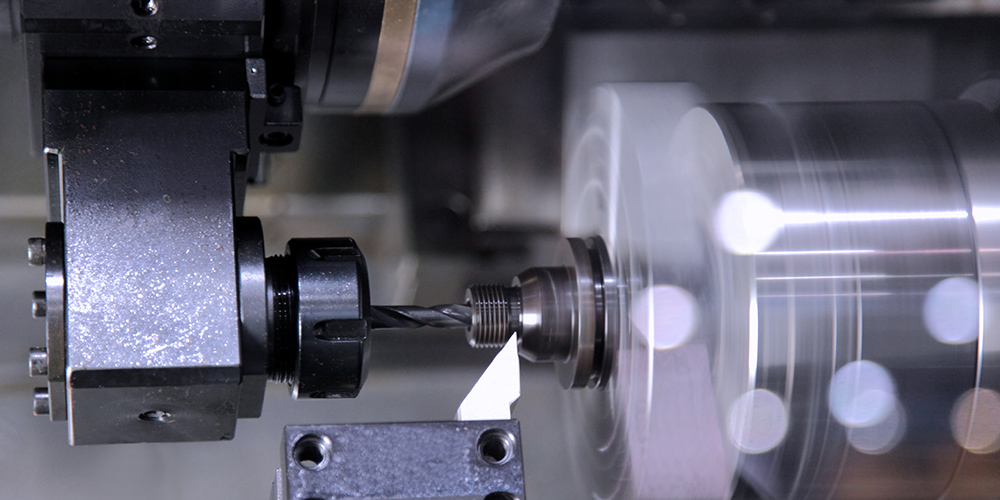

Design For Manufacturing

Design for manufacturability (also sometimes known as design for manufacturing or DFM) is the general engineering art of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing.

Contract Manufacturing Service Area

Rowe Dynamics Inc. can provide Manufacturing Design Analysis Services to organizations throughout the U.S. and the World.

Benefits of Rowe Design Analysis

- Increased Quality - improves on time delivery reliability and increases production output with fewer defects.

- Increased Efficiency - proper project management allows us to ensure our competitive edge and keeps our customers happy.

- Increased Responsiveness - streamlined processes making better products and solutions for our customers.